Surprising fact: nearly one in four roadside failures start with a battery or charging fault—small voltage shifts can ground a trip fast.

We’ll walk a clear, high-level plan for the work ahead. First, we use a calibrated volt gauge and a factory service manual. That keeps us honest. It lets us test the electrical system rather than guess.

Think of the battery as an amperage storehouse at about 12.6 volts. Alternators must meet the car’s load and then recharge that store after start. Voltmeter readings rise as the battery nears a fully charged state.

We set success early—stable volt readings near spec while under load and a battery that returns to full after driving. Safety comes first—no sparks near the battery. Next, we follow a simple order: grounds, connections, fuses, then high‑draw circuits. From there, deeper component checks make sense.

Key Takeaways

- Start with a clear plan and the right manual.

- Use a calibrated volt gauge for repeatable readings.

- Watch for volt rise as the battery reaches a fully charged state.

- Check grounds, fuses, and connections before swapping parts.

- Prioritize safety—avoid sparks and secure terminals.

Safety First: Preventing Battery Explosions and Electrical Burns

Safety is the first tool we reach for—small mistakes near a battery can become big injuries. We always pause, ventilate, and remove ignition keys before any tests. A calm approach keeps us safe and protects our tools.

No sparks or flames near batteries; notice sulfur smells

If you smell sulfur—like rotten eggs—stop work and ventilate immediately. Those fumes can ignite from a single arc. Keep all sparks and flames away and have a class ABC extinguisher staged nearby.

Protecting meters and probes when checking continuity

We never use an ohm meter on a live circuit. Pull power first and verify the circuit is de-energized. A live check can blow the meter’s internal fuse or ruin the instrument.

- Inspect posts and cases for damaged acid leakage and a leaking side post—corrosion raises resistance and heat risk.

- Disconnect the negative cable first, especially if the cable vehicle jumped recently. That cuts the chance a wrench shorts to chassis ground.

- Wear gloves and eye protection when probing any wire carrying current. Remove rings and watches to prevent welding burns.

- Keep test leads clear of belts and fans, neutralize small acid with baking soda and water, and keep keys out of the ignition while working.

Tools and References You Need Before You Start

Good results start with the right gear—reliable meters, clean probes, and the factory paperwork. We gather tools that give repeatable numbers and protect the car while we test the electrical system.

Calibrated meters, test lights, and the paper you trust

Bring a calibrated volt gauge. It makes readings trustworthy when you compare values to the factory service manual. A quality test light and a fuse‑protected multimeter save time and protect your tools.

On‑car voltmeter behavior and safe continuity checks

In a voltmeter equipped corvette, expect lower charging volts just after a hard start. The alternator will deliver high amps into a low battery, then the voltage rises as the battery nears full.

- When you use an ohm meter, pull power first—this prevents blown fuses in the meter.

- Keep wiring diagrams and connector views from the manual handy— they point out splice and ground locations.

- Carry back‑pin probes, extra fuses, contact cleaner, and a fused jumper lead for safe bench tests.

- Label wires and photograph connectors before disassembly. A torque wrench for battery posts prevents damage.

How to Diagnose Electrical Problems in a Corvette Stingray: A Step‑by‑Step Workflow

We start every repair with a steady, step‑by‑step workflow that finds faults without guesswork. Small checks first, deeper tests next—this keeps us efficient and safe.

Visual inspection. Scan for a leaking side post, melted insulation, and any wire harness damaged by heat or abrasion. Look where harnesses bend or pass sharp brackets; those spots hide the worst faults.

Ground checks. Tug test the black ground wire at each chassis and engine anchor. Green corrosion or loose eyelets makes intermittent faults. Clean or replace loose ground straps.

Voltage and load. Verify battery state with a calibrated volt gauge. Then load the entire electrical system—headlights, blower, and rear defog—so weak links reveal themselves.

Voltage drop tests. Measure across positive and negative sides while loads run. More than a few tenths of a volt means cleaning, tightening, or repair.

“A short occurs when a wire carrying current touches ground; an open breaks the path and kills the circuit.”

- Isolate opens vs shorts—an open is a dead circuit; a short is when current touches ground and usually blows a fuse.

- Trace driving-only faults where the harness can rub—these are classic carrying current touches events.

- Use the factory service manual for ground trees, splice packs, and probe points.

- Back‑probe connectors, wiggle test gently, then pull fuses one at a time to isolate branches.

Repair right. Solder and heat‑shrink in dry locations. Use weather‑sealed splices underhood. That gives a lasting fix and fewer returns.

Batteries and Cables: The Storehouse and Arteries of Your Stingray

The battery is the car’s storehouse; cables are the arteries that keep current flowing. We help you choose and maintain the right battery and cables—critical when diagnosing starting and charging faults.

Cold cranking needs. Large cubic inch engines draw heavy current. For cubic inch high builds and high compression engines, choose a battery with higher CCA. In short, compression engines require extra torque at crank—low CCA risks starter heat and flywheel damage.

Grounds and returns. Clean the engine ground cable and the frame engine ground so starter current returns without loss. Test voltage drop across the positive run and the black ground wire during cranking; any reading above spec means cleaning or replacement.

Corrosion and damage. Look for damaged acid leakage and a leaking side post. Corroded lugs raise resistance and cause slow cranks or intermittent no‑starts. After cleaning, use dielectric grease on posts—don’t insulate the metal joint.

- Size cables to the amperage load starter demands; undersized wire heats and fails.

- Route and secure cables away from headers; add loom where chafe may occur.

- Prefer OEM‑style crimped terminals and recheck torque after a week, especially after a cable vehicle jumped event.

| Item | Recommended Action | Why it Matters | Example Spec |

|---|---|---|---|

| Battery CCA | Match to engine size | Prevents starter overload | Higher CCA for large cubic inch engines |

| Cable Gauge | Use heavier gauge for high draws | Reduces heat and voltage drop | Gauge sized to amperage load starter |

| Grounds | Clean and torque properly | Ensures solid return path | Frame engine ground and engine ground cable cleaned |

| Posts & Terminals | Replace corroded lugs | Prevents resistance from damaged acid leakage | Avoid leaking side post; use dielectric grease |

Understanding Amps, Volts, and Ohms to Avoid Misdiagnosis

Simple analogies—pressure, flow, and friction—keep electrical testing on track. Volts are pressure. Amps are flow. Ohms are resistance. This mental model keeps our tests focused on what the electrical system actually needs.

Relays and many devices are coils where a component uses resistance to make a magnetic field. Corrosion raises that resistance and weakens the device. Voltage drop steals pressure, so motors run slower and run hot.

Never use ohm meter on a live circuit. Isolate the part, test, then reconnect. An ohm reading on a disconnected sender matters because gauges work resistance to display fuel, temperature, and oil levels.

Long, thin wire adds resistance. Better routing or heavier gauge prevents drop on high‑draw runs. Bad grounds make gauges lie; a known good ground jumper helps confirm if the ground path is the culprit.

- Baseline checks: battery at rest, key on, engine running.

- Do voltage drop tests under load — that reveals hidden loss.

- Keep a cheat sheet in your tool lid with target ranges and quick steps.

“Think pressure, flow, and friction—your voltmeter and amp clamp will start telling the truth.”

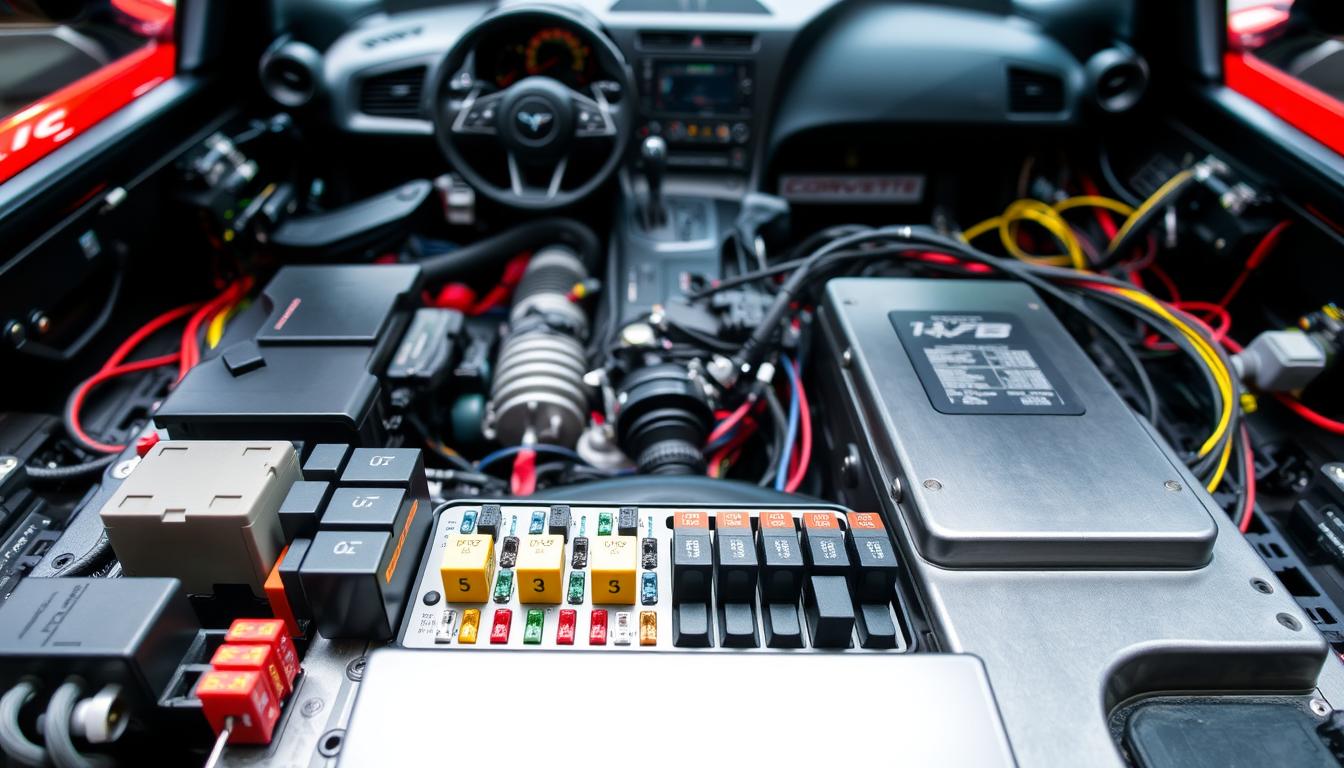

Fuses, Maxi‑Fuses, and Circuit Breakers Used in Corvettes

Protection starts at the battery and moves out through fuses, maxi‑fuses, and resettable breakers. Early cars used simple blade fuses. In 1968 fuse links protected major runs. Later, manufacturers moved those links to heavy maxi‑fuses near the battery to save harness repair when a short occurs.

Which circuits use circuit breakers used: high inrush items like blower motors, wipers, defoggers, windows, and power seats. Breakers trip on overload, then reset—perfect for motors that draw extra current at start.

Never upsize a fuse. A fuse is sized so a wire carrying current opens before the harness overheats. Upsizing risks melting insulation and fire. Modern cars use lighter gauge wiring for weight savings, so there is less margin if someone fits a larger fuse.

- Check seized motors—when a component uses resistance, a stuck rotor draws much more current.

- Measure current draw against spec to decide if the fault is the load or a short to ground.

- To find a recurrent blown fuse, pull branch plugs until the fuse holds. That back‑tracks the failing leg.

- Rain‑only shorts often live in boots or grommets—water gives a path where current touches ground.

“A blown fuse points at a fault. Trace the circuit—repair the cause, not just the fuse.”

Repair with proper sized fuses, sealed splices, and secure routing. Confirm resettable breakers do not chatter under normal use before calling the job done.

Charging System Checks: Generators, Alternators, and Regulators

A quick charging sweep gives clear answers without guesswork. We show practical checks you can run at home. Keep safety first—gloves and eye protection when near the battery.

Mechanical and tape regulators on early cars

First, identify what you have. Early Corvettes used DC generators with mechanical voltage regulators. Later models used alternators with tape style regulators.

Generators pulse differently at idle. Mechanical voltage regulators may need adjustment or polarization after service. Tape style regulators show a steadier control but can drift with heat.

Reading output when a low battery would demand high amps

Connect a voltmeter equipped corvette and watch voltage right after start. A low battery would pull the system voltage down while the alternator or generator delivers high amperage.

Raise RPM to 1,500–2,000 and switch on the radiator cooling fan and headlights. The charger should keep voltage above the battery resting level as the battery nears a fully charged state.

- Check belt tension and pulleys—slip mimics failure.

- Measure AC ripple at the battery; high ripple means bad diodes.

- Inspect the charge wire path for corrosion—resistance starves the entire electrical system.

- Compare cold versus hot regulator readings; heat often reveals drift.

“Document idle and 1,500–2,000 rpm readings. A baseline saves time on later faults.”

| Check | What to Watch | Expected Result |

|---|---|---|

| Idle volts | After start, key on | 12.6–13.0V (rising if charging) |

| Load test | Fan + lights at 1,500–2,000 rpm | Voltage stays above resting level |

| AC ripple | Diode test at battery | |

| Generator polarity | After rebuild/polarize | Correct output direction per manual |

Starter and Solenoid Diagnostics for Hot and Cold Starts

We watch crank speed and voltage recovery — those numbers tell us if a starter or the supply is at fault.

Amperage spikes at crank hurt windings when voltage drops. We measure volts at the battery and at the starter while cranking to see how the amperage load starter pulls the circuit. A large drop at the starter means bad cables, loose lugs, or poor grounds.

Delco direct‑drive units draw more than later gear‑reduction starters. NipponDenso gear‑reduction designs (1988+) cut current demand and help hot starts on tight engines. For a large cubic inch build with an inch high compression ratio, choose higher CCA and stout cables — compression engines require extra cranking torque.

Check the solenoid trigger for solid voltage. Thin or corroded trigger wires mimic starter failure. Inspect engine‑to‑frame straps — bad returns look like weak batteries but are simple resistance faults.

| Item | Symptom | Test | Action |

|---|---|---|---|

| Voltage drop | Slow crank | Measure battery vs starter during crank | Clean terminals, replace cables |

| Starter type | High draw or efficient draw | Compare Delco vs gear‑reduction current | Upgrade to gear‑reduction if needed |

| Solenoid trigger | Click but no spin | Back‑probe trigger for full battery volts | Repair or replace thin/corroded wire |

| Hot soak | Kickback or rough restart | Load‑test battery hot and cold; bench starter | Add heat shield, reroute cables, bench repair |

“Confirm cranking speed and immediate voltage recovery at the battery after the start completes.”

Grounds and Resistance: The Hidden Causes of Intermittent Faults

A poor ground often hides behind flickering lights and slow motors—yet it’s easy to find if we use a simple method.

What a resisted ground circuit does. Added resistance skews gauges, creates heat, and drops voltage under load. Fuses may sit fine while the return path fails during use.

Where we look first. Start at the frame engine ground and the main straps underhood. Remove paint and rust, then tighten with a star washer so the clamp bites metal cleanly.

Check the black ground wire lugs for green corrosion or heat discoloration. If strands are broken or insulation is hard, replace the engine ground cable with a stout OEM‑style unit.

Meter voltage drop on the return side while loads run. More than ~0.2 V on grounds needs work.

Use supplemental ground jumpers to prove a symptom clears with a better path. Treat cleaned contacts with conductive anti‑corrosion compound and secure leads with strain relief.

“Repeat drop tests with the same loads—numbers must improve, not just the symptom.”

| Symptom | Likely Ground | Quick Action |

|---|---|---|

| Dim lights under load | frame engine ground | Clean, sand, tighten with star washer |

| Slow blower or starter | engine ground cable | Inspect strands, replace if brittle |

| False gauges | black ground wire | Back‑probe, measure return drop, secure lug |

Wiper Motors and Controls: Early vs Late Corvette Systems

Wiper systems change a lot across model years; knowing which design you have saves time at the bench. We map year ranges so you probe the right places and avoid chasing the wrong diagram.

63–77 wiring logic

Used early Corvettes from 63–77 select speeds by completing ground paths. In those cars the motor speeds controlled by the switch rely on grounding, not multiple hot feeds.

68–72 column override

The override switch column sits under the dash on 68 models. From 69–72 its interrupt logic changes how the override breaks power. Probe ground terminals at the switch when testing these cars.

78–82 delay module

From 78–82 the switch commands a separate wiper delay module. Jump the module input to confirm if a speed or park fault lives in the module or the motor.

84–96 covered electronics

84–96 units house electronics under a black plastic cover. This cover often fails after engine work. The .84 shorthand (.84 wiper motors) refers to that era; protect the cover during service.

“Test power and ground at the motor first. A quick jumper separates motor failure from control logic.”

| Years | Control Type | Quick Test |

|---|---|---|

| 1963–1977 | Ground‑selected speeds | Back‑probe grounds at switch |

| 1968–1972 | Column override logic | Check override contact under column |

| 1978–1982 | Switch + wiper delay module | Bypass module with jumper wire |

| 1984–1996 | Motor electronics under black plastic cover | Inspect cover, probe motor power/park |

Blower Motors and Radiator Cooling Fans: High‑Draw Components

High‑draw loads like blower motors and cooling fans reveal wiring faults fast when we test them properly. These parts hide resistance that makes other systems act up. We show simple checks that separate a failing motor from a wiring or protection problem.

Why resistors matter for blower speed

The HVAC component uses resistance to create stepped speeds. Blower resistor packs drop voltage so the motor speeds controlled by the switch run slower at lower settings.

Check packs for burned coils and heat damage. Airflow cools the pack — a blocked duct raises resistance and cuts speed.

Testing fans, current draw, and protection

Measure current on like blower motors at each speed. A dragging motor shows high amps and heats the circuit. Test a radiator cooling fan with direct power and watch spin‑down time; stiff bearings spike draw.

Radiator cooling fans running constantly often point at a bad sensor, relay, or wiring fault. That constant run raises alternator load and strains the entire electrical system.

- Verify that circuit breakers used reset cleanly — chatter mimics motor faults.

- Inspect connectors for heat discoloration and melted plastic — those add resistance.

- Confirm core support and fan module grounds — a bad ground hides real problems.

- Load‑test a wiper motor or other high‑draw device the same way — compare current to spec, not just motion.

Finish with cleaning shrouds and ensuring blades clear the housing. Small drag kills motor life and masks the real fault under the fan.

Dash Gauges and Senders: Fuel, Oil Pressure, and Tach Diagnostics

Gauges can mislead; a few simple resistance tests clear the confusion. We start by remembering that gauges work resistance. Small changes in ohms make big swings on the needle.

Fuel sender checks and common reading errors

The fuel gauge sender reads roughly 0 ohms at empty and ~90 ohms at full. A corroded lead or poor connector adds resistance and makes the gauge read higher than the tank.

Unplug the sender and substitute known resistances—0 ohms and ~90 ohms—while watching the cluster. That proves the gauge and separates a bad sender from wiring loss.

Oil pressure behavior and what it means

An oil pressure gauge that pegs high usually points at an open circuit. If it reads zero, the sender or harness is likely grounded. We check continuity back to the cluster and inspect shared grounds that skew multiple instruments.

Tach oddities after jump starts and charging checks

If someone use reverse polarity during a cable vehicle jumped attempt, the tach needle can stick near redline. Most recover after a few normal starts. We advise watching the cluster while using a voltmeter equipped corvette—voltmeter readings rise toward a fully charged state as the battery recharges from a cold start or when a low battery would demand high amps.

“Verify sender resistance, then trace wiring—fix the path, not just the needle.”

- Clean and tighten sender connectors; tiny resistance shifts matter.

- Use continuity checks and gentle wiggle tests for intermittent opens.

- Prefer voltmeters over ammeters for cluster checks—voltmeters are safer and more informative.

Sender replacement checklist: remove old sender, clean thread, use Teflon paste sparingly so it doesn’t insulate the ground, torque to spec, and recheck resistance at the connector.

Early vs Late Corvette Wiring: From Heavy Loads to Lighter Gauge Wiring

From fat cables and few accessories to thin harnesses packed with modules, wiring changed fast. We give context so you test the right way for your generation.

Used early corvettes came with heavy wiring and simple circuits. They relied on robust feeds and mechanical voltage regulators or early alternators with tape style regulators. Those systems tolerate some abuse but suffer when a wire harness damaged by heat appears.

After 1997 modular controls cut current draw. Manufacturers used lighter gauge wiring and many modules. That saves weight but makes stable voltage and clean grounds critical. Poor returns look like module failures.

Large builds raise a special risk. A large cubic inch or cubic inch high engine draws far more cranking current than stock. Early wiring may need upgrades for reliable starts.

| Era | Typical Wiring | Common Faults |

|---|---|---|

| Pre‑1997 | Heavier gauge, simple circuits | Chafing near headers, corroded grounds |

| 1997+ | Lighter gauge, modular controls | Voltage drops, module brownouts |

| Classic with big engine | Stock wire + high demand | Slow crank, heat at lugs |

- Add dedicated grounds and relay kits on older cars.

- Route and shield wiring near exhaust and sharp edges.

- Scan TSBs for year‑specific connector or ground fixes.

How to Diagnose and Fix Electrical Issues in a Corvette Stingray

We run a quick, focused checklist that clears the usual suspects fast. Start with safe meter readings and a calm work area. Small faults hide behind dirty grounds and tired fuses.

Checklist: fuses, grounds, voltage drop, alternator output, and switch integrity

Quick checklist:

- Verify battery health and confirm alternator output at idle and 1,500 rpm.

- Inspect and clean grounds; measure voltage drop under cranking and loaded conditions.

- Pull and check fuses and circuit breakers used on high‑draw circuits for heat marks and loose tension.

- Test brake light switch and turn signal switch for continuity under load.

Targeted checks: brake light switch, turn signal switch, wiper motor, wiper delay module

Command the wiper motor and watch wiper motor speeds across settings. If speeds jump or stall, bypass the wiper delay module or swap motors to isolate the fault.

Brake and turn switches on older cars carry real current—verify they pass full volts when operated. Replace or repair corroded contacts rather than fusing higher.

When the current touches ground: tracing intermittent shorts under vibration

Shorts happen when a wire carrying current touches metal. Wiggle looms while watching the meter. If a fuse pops when you flex a harness at a hinge, you’ve found the suspect zone.

“Trace the symptom while you move the harness—vibration will show intermittent shorts faster than a static check.”

| Fault | Quick Test | Action |

|---|---|---|

| Intermittent fuse blow | Wiggle harnesses at grommets | Repair chafe, re‑loom, heat‑shrink, strain relief |

| Dim lights under load | Voltage drop at frame and starter | Clean grounds, replace cable if >0.2V drop |

| Random wiper failure | Command motor, bypass delay module | Replace motor or module; secure cover |

Are Chevys Known for Electrical Issues? Context for the Corvette Owner

Many drivers blame the make—yet most faults track back to age, heat, or prior repairs. We look at whether early late model design choices matter, and what owners can do about them.

Used early corvettes often show the usual signs of wear: corroded grounds, brittle connectors, and tired harness insulation. Those parts simply age. Refreshing grounds and cleaning connectors removes most surprise faults.

Later models adopted lighter gauge wiring and modular controls to save weight. That change works well—until poor grounds or damaged splices create brownouts. Perfect grounds and protected runs are now more important than ever.

Protection improved too. Maxi‑fuses and the circuit breakers used on high‑draw circuits limit harness damage better than old fuse‑link strategies. That reduces catastrophic failures and makes repairs cleaner.

Preventive maintenance matters. Clean grounds, shield harnesses from heat, and fix small faults early. We also recommend checking service bulletins for year‑specific connector or module fixes.

Upside: parts are plentiful and the community is eager to help. With a steady workflow and a few good tools, most mystery faults yield quickly.

“Document repairs—future you, or the next owner, will thank you.”

- Age and heat cause most complaints—not brand alone.

- Refresh grounds on used early corvettes first.

- Protect runs where lighter gauge wiring passes exhaust or sharp edges.

- Use proper maxi‑fuses and circuit breakers used for high‑draw loads.

What Is the Life Expectancy of a Corvette Stingray?

A Corvette can outlast many cars when owners treat electrical care as routine. With steady attention, these cars often run for decades and hit high mileage without drama.

Electrical reliability is central. Clean battery posts and solid frame engine ground points stop heat and hidden resistance. That keeps starters, alternators, and modules from working harder than they should.

Wiring under the hood takes heat and moisture. Interior harnesses age from constant current flow. Replace brittle sections and shield wires near exhausts and sharp edges.

Practical steps we recommend:

- Inspect and replace an aged engine ground cable and key straps every few years in harsh climates.

- Run annual voltage drop checks during service to catch creeping resistance early.

- Use OE-quality connectors and weather seals for lasting repairs.

- Keep the battery on a maintainer during long storage—stable voltage extends module life.

Fans, blowers, and starters live longer when the charging system is cleanly grounded. With proactive care, life expectancy is limited more by owner attention than by the platform itself.

Conclusion

Finish strong by proving the numbers, not just the symptom.

We close with a simple workflow: inspect, measure, load test, isolate, repair. Start with battery health, clean grounds, and tight connections. Those basics fix more faults than swapping parts.

Remember era differences — generators versus alternators, fuse strategy, and wiper logic change test points. High‑draw circuits like starters, blowers, and fans suffer when voltage drop steals performance. Maxi‑fuses and circuit breakers protect wiring if sized correctly.

Gauges follow resistance values. Verify sender ohms before you replace the cluster. Chevy reliability holds when owners maintain connections and record baselines.

Keep notes, build a baseline, and use this guide as a repeatable checklist. We’ve got your back—stay safe and enjoy the drive.

FAQ

What basic safety steps should we take before working on the battery?

Keep sparks and flames away — battery gas can ignite. Wear eye protection and gloves. If you smell sulfur, stop work and ventilate. Disconnect negative cable first, and protect tools from bridging posts. Don’t lean over the battery when cranking.

How do we protect our multimeter when using an ohm meter for continuity?

Remove power from the circuit before measuring resistance. Isolate the component from the harness when possible. Use correct range and probe insulation. A fused meter and a calibrated volt gauge help avoid damage from accidental live connections.

Which tools and references should we have before starting diagnostics?

A calibrated voltmeter, test light, good ohmmeter, battery load tester, and the factory service manual for your year. A wiring diagram speeds tracing, and a voltmeter-equipped Corvette makes charging behavior easier to read under load.

What should we look for during the initial visual inspection?

Check the wire harness for chafing or damage, inspect side post areas for leaking acid, and verify black ground wire and engine ground cable integrity. Look for corroded terminals, melted insulation, and evidence of past overheating.

When should we perform voltage drop tests on the electrical system?

Run voltage drop tests while the circuit is under typical load — starter cranking, lights on, or coolant fans running. Measure across connections and along cables to find high-resistance points causing dim lights or slow cranking.

How do we tell an open circuit from a short to ground?

An open shows infinite or very high resistance; the circuit won’t energize. A short to ground shows near-zero resistance and often blows fuses or trips breakers when energized. Trace the wire path and wiggle harnesses to find intermittent contacts.

What battery and cable specs matter for big cubic‑inch or high-compression engines?

Use a battery with sufficient cold cranking amps (CCA) and a low internal resistance for high-compression engines. Heavy gauge battery cables and a clean, solid engine-to-frame ground keep starter amperage load down and voltage stable.

How do we clean and secure engine and frame grounds?

Disconnect the battery, remove the ground connection, clean to bare metal with a wire brush, apply dielectric grease, and re-tighten. Inspect the engine ground cable for corrosion or broken strands and replace if compromised.

What hazards come from damaged side posts or acid leakage?

Acid can corrode posts, cables, and surrounding wiring — causing resistance, shorts, or broken connections. Replace damaged terminals, neutralize acid, and inspect nearby harnesses for insulation damage.

Why do Corvettes use circuit breakers instead of just fuses?

Circuit breakers protect high-draw accessories — blower motors, wipers, power seats — by resetting after temporary overloads. They avoid repeatedly replacing fuses and protect wiring that sees intermittent high current.

Why must we avoid upsizing fuses?

Oversized fuses let excessive current flow and can melt wiring before the fuse blows. Use the OEM rating or correct maxi‑fuse replacements; they’re sized to protect the original wire gauge and components.

How do we check alternator output on a weak battery?

With a good battery or proper load, measure system voltage at idle and during a moderate rpm increase. A healthy alternator should raise voltage to the specified range. If alternator output stays low when the battery demands high amps, test diodes and regulator function.

Are there special regulator types on early Corvettes?

Yes — some early Corvettes used mechanical voltage regulators or tape style regulators. They require specific service procedures and may behave differently than modern solid‑state regulators when testing.

How do we test starter amperage and detect voltage drop effects?

Use a clamp‑on ammeter or starter load tester to read cranking amps. Simultaneously monitor voltage at the starter and battery. High voltage drop between them indicates bad cables, poor grounds, or corroded terminals affecting cranking performance.

What starter issues occur with high‑compression engines?

High‑compression engines demand more starter amperage and can cause starter kickback on some designs. Delco and gear‑reduction starters behave differently; inspect engagement, solenoid operation, and mounting integrity.

How do resisted ground circuits show up and how do we fix them?

Symptoms include dim lights, intermittent accessories, or gauges that read incorrectly. Clean ground points, replace corroded straps, and ensure tight, paint‑free contact areas. Sometimes adding a short diagnostic ground pin helps locate the bad connection.

What differences exist between early and late wiper systems?

Early models (1963–77) often control speeds by grounding different motor terminals and may include an override switch in the column (1968–72). Later systems (1978–82) use different switch logic, and 1984–96 motors include black plastic cover electronics and delay modules like the .84 motor variants.

How do blower resistors and motor speed controls fail?

Blower motors rely on resistors or electronic modules for speed steps. A failed resistor or poor ground will force full speed or no operation. Test resistance values and supply voltage at each resistor tap while cycling speed settings.

How do radiator cooling fans affect the whole electrical system?

Cooling fans draw large current and can reveal weak alternators, poor grounds, or undersized wiring. A fan running constantly may indicate a faulty temperature sensor, relay, or thermostat; a fan that stalls under load points to wiring or power supply problems.

What are common gauge and sender faults for fuel and oil systems?

Fuel senders commonly range 0–90 ohms; an open reads very high, and a short reads near zero. Oil pressure gauges can peg high with open circuits or read zero when grounded. Test sender resistance and wiring for opens, shorts, or poor grounds.

Why might the tach stick after a reverse‑polarity jump start?

Reverse polarity can damage ignition modules, signal grounds, or the tach’s input circuitry. After a wrong‑polarity jump, check fuses, ignition components, and the tach input wiring; some units recover after correcting the wiring and clearing codes.

How do wiring differences between early and late models affect repairs?

Early Corvettes used heavier wiring and fewer electronics, making some repairs simpler but heavier on current draw. From 1997 onward, modular controls and lighter gauge wiring reduce current capacity and require careful diagnosis of module faults and connector corrosion.

What basic checklist should we follow when tracing a tricky electrical fault?

Start with fuses and breakers, confirm clean grounds, perform voltage drop checks, verify alternator output, and test switch integrity. Target likely suspects — brake light switch, turn signal switch, wiper motor or delay module — and wiggle harnesses to find vibration‑induced shorts.

How do we trace intermittent shorts that appear only under vibration?

Recreate the condition — drive or bounce the car safely while monitoring the circuit. Use backprobing and gentle flexing of harness sections. Look for insulation rubbed down to copper, chafed wires contacting metal, or loose connector pins.

Are Chevy Corvettes known for electrical gremlins compared with other cars?

No model is immune — older Corvettes can show age‑related wiring, ground, and connector problems. Regular inspections, cleaning grounds, and preventing acid leakage extend reliability. Modern Corvettes have complex modules that need systematic scan and power checks.

What is the expected life span of a Corvette from an electrical standpoint?

With proper maintenance — clean grounds, corrosion control, timely harness repairs, and correct fusing — the electrical system can last decades. Component life varies: batteries, starters, and alternators wear over years; wiring lasts longer if protected from heat and acid.

Recent Posts

Looking for a quick, affordable way to customize your bike? Discover why this simple oil filler cap is the must-have mod for your CBR 650 R.

Keep your Perkins engine protected with our ultimate quality replacement oil filler cap. It's designed to deliver a perfect, leak-proof seal for lasting performance and peace of mind.