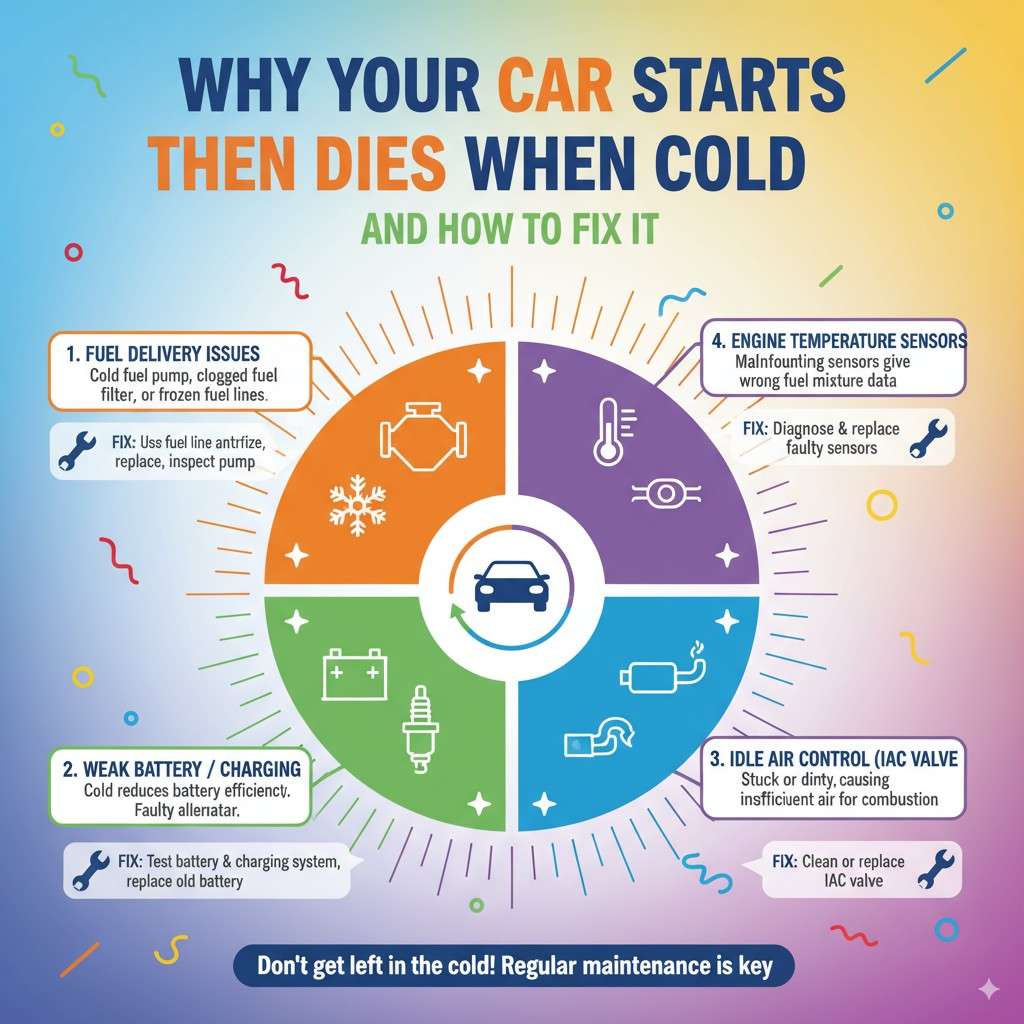

Quick Summary: If your car starts then dies when cold, it most likely has a fuel or air delivery issue. Common culprits include a dirty mass air flow sensor, a failing idle air control valve, vacuum leaks, or a weak fuel pump. Addressing these can get your car running smoothly in chilly weather.

That moment when your car starts, roars to life, and then… immediately gives up the ghost. It’s a common and frustrating problem, especially when the temperature drops. You turn the key, the engine catches, and then, sputtering, it dies. This can make your morning commute feel like a guessing game. But don’t worry! This isn’t a sign you need a whole new engine. Often, this “starts then dies when cold” issue has simple, fixable causes. We’ll walk through the most likely reasons and what you can do about them, making your car reliable again, even on the frostiest mornings.

Why Your Car Might Be Stalling When Cold

When an engine is cold, it needs a different fuel-air mixture than when it’s warm. It requires a richer blend (more fuel, less air) to ignite and run smoothly until it reaches its optimal operating temperature. If something is preventing the car’s computer from sensing or providing this richer mixture, it might start up, then choke itself out and die. Think of it like trying to sip soup through a thick straw – it’s difficult for the engine to get what it needs to keep running.

Several components play a crucial role in managing this cold-start process. When one of these parts isn’t working correctly, especially in cooler temperatures, the engine just can’t get going properly. The good news is, most of these issues are relatively straightforward to diagnose and fix, even for DIY beginners.

Common Causes and How to Fix Them

Let’s dive into the most frequent culprits behind your car starting and then dying when cold. We’ll break down each one, explain why it causes the problem, and guide you through potential solutions.

1. The Mass Air Flow (MAF) Sensor Isn’t Pulling Its Weight

The Mass Air Flow sensor (MAF) is like the car’s air traffic controller. It measures the amount of air entering the engine. This information is critical for the car’s computer (ECU) to calculate exactly how much fuel to inject. When the MAF sensor gets dirty or faulty, it sends incorrect readings, especially when the engine is cold and needs precise air intake measurements.

- Why it causes the problem: A dirty or failing MAF sensor can tell the ECU that too much or too little air is entering the engine. This leads to the wrong fuel mixture, causing the engine to stumble and stall after starting. Cold air is denser, so the MAF needs to be especially accurate then.

- How to fix it:

- Cleaning: Often, the MAF sensor is just dirty. You can clean it with a specialized MAF sensor cleaner spray. First, locate your MAF sensor (usually found in the intake hose between the air filter box and the engine). Carefully disconnect its electrical connector. Remove the sensor (consult your car’s manual or online resources for specific instructions). Spray the sensor element generously with MAF cleaner, allowing it to air dry completely. Never touch the sensor element with your fingers or any other object. Reinstall and reconnect.

- Replacement: If cleaning doesn’t help, the MAF sensor might be faulty and need replacement. This is usually a straightforward part swap.

Pro Tip: Always use MAF sensor cleaner specifically designed for this purpose. Regular brake cleaner or carburetor cleaner can damage the sensitive electronics.

2. Vacuum Leaks Are Letting Unwanted Air In

Your engine relies on a precise balance of air and fuel. Vacuum leaks are essentially unintended air intrusions into the engine’s intake system. This unmetered air messes with the air-fuel ratio calculated by the ECU, which is even more critical when the engine is cold.

- Why it causes the problem: Extra air entering after the MAF sensor means the engine is getting more air than the ECU is accounting for. When cold, the engine needs a richer mixture, but the leak leans it out, causing it to stall.

- How to fix it:

- Visual Inspection: Look for cracked, loose, or disconnected vacuum hoses. Pay close attention to rubber hoses connected to the intake manifold, throttle body, and brake booster.

- Listening: With the engine running (if it stays running long enough), carefully listen for hissing sounds around the intake system.

- Smoke Test: For more persistent leaks, a mechanic can perform a smoke test. They introduce smoke into the intake system, and where the smoke escapes, you’ve found your leak. You can also purchase DIY smoke testing kits.

- Replacing Hoses: If you find a damaged hose, replacing it is usually a simple DIY task. Make sure to get the correct diameter and type of hose.

A common place for vacuum leaks is around the intake manifold gasket or throttle body gasket.

3. The Idle Air Control (IAC) Valve Isn’t Managing the Idle

The Idle Air Control (IAC) valve is responsible for regulating the engine’s idle speed. When you decelerate or come to a stop, the throttle plate closes, and the IAC valve opens a small bypass, allowing just enough air to keep the engine running without stalling. When the engine is cold, the IAC valve often needs to allow more air to compensate for the less efficient combustion, but if it’s stuck or dirty, it can’t do its job.

- Why it causes the problem: If the IAC valve is stuck closed or not opening enough, the engine won’t get enough air to maintain an idle, especially when cold. It starts up fine, but as soon as it needs to idle on its own, it dies.

- How to fix it:

- Cleaning: The IAC valve can become gummed up with carbon deposits. Locate it (often near the throttle body) and remove it. Spray it thoroughly with throttle body cleaner or carburetor cleaner, paying attention to the valve and its passageways. Clean the port it mounts into as well. Ensure it moves freely.

- Replacement: If cleaning doesn’t resolve the issue, the IAC valve may have failed electronically or mechanically and will need to be replaced.

Important Note: Some newer vehicles have an electronic throttle body that manages idle speed without a separate IAC valve. In these cases, the throttle body itself might need cleaning or have a fault.

4. The Engine Coolant Temperature (ECT) Sensor is Misleading the ECU

The Engine Coolant Temperature (ECT) sensor tells the car’s computer how hot (or cold!) the engine is. This information is crucial for the ECU to adjust the fuel mixture. When the engine is cold, the ECU enriches the fuel mixture. If the ECT sensor is faulty and incorrectly tells the ECU the engine is already warm, the ECU will provide a leaner mixture, which is insufficient for a cold engine.

- Why it causes the problem: The ECU thinks the engine is warmer than it is. It then injects less fuel than needed for cold combustion, causing the engine to sputter and die immediately after starting.

- How to fix it:

- Diagnosis: A mechanic can test the ECT sensor’s resistance at different temperatures using a multimeter to see if it’s within specifications. You can also check for diagnostic trouble codes (DTCs) related to the ECT sensor.

- Replacement: If the sensor is faulty, it needs to be replaced. This is often a relatively easy DIY job, but you’ll need to let the engine cool down completely first.

You can find reputable diagnostic tools and information on automotive sensors at resources like AutoZone’s technical guides or similar automotive repair sites.

5. Fuel Delivery Issues: Not Enough Gas When It Counts

Even if your car starts, if it’s not getting enough fuel, it won’t stay running. This can be due to several fuel system problems, especially noticeable when cold.

a) Weak Fuel Pump: The fuel pump is responsible for pushing gasoline from the tank to the engine. If it’s weak, it might provide enough fuel for the initial start but struggle to maintain consistent pressure for sustained running.

- Why it causes the problem: A weak fuel pump can’t deliver the necessary volume or pressure of fuel, especially under the increased demand of a cold start.

- How to fix it:

- Pressure Test: A mechanic can perform a fuel pressure test to see if the pump is delivering the correct pressure.

- Replacement: If the fuel pump is weak or failing, it will need to be replaced. This can be a more involved job, sometimes requiring access under the rear seats or removal of the fuel tank.

b) Clogged Fuel Filter: The fuel filter removes debris from the gasoline. A clogged filter restricts fuel flow to the engine. This restriction can be more pronounced when the engine demands more fuel for a cold start.

- Why it causes the problem: A dirty fuel filter chokes off fuel supply. The engine starts, but then it can’t draw enough fuel to keep running.

- How to fix it:

- Replacement: The fuel filter is a maintenance item and should be replaced periodically according to your vehicle’s service schedule. It’s often an accessible component near the fuel tank or along the fuel line.

c) Issues with the Fuel Pressure Regulator: This component maintains the correct pressure in the fuel rail. If it fails, the fuel pressure can be too high or too low, affecting how the engine runs.

- Why it causes the problem: Incorrect fuel pressure can lead to a rich or lean condition. A lean condition (too little fuel) caused by a faulty regulator can make a cold engine stall.

- How to fix it:

- Diagnosis: Fuel pressure tests can identify issues with the regulator.

- Replacement: A faulty fuel pressure regulator will need to be replaced.

Troubleshooting Steps: A Beginner’s Guide

If you’re new to car maintenance, tackling these issues can seem daunting. Here’s a step-by-step approach to help you diagnose and potentially fix the “starts then dies when cold” problem.

- Check the Basics First:

- Battery: While a weak battery usually prevents starting altogether, a severely corroded terminal could cause intermittent issues. Ensure battery terminals are clean and tight.

- Is the “Check Engine” Light On? If so, this is your biggest clue! Get the codes read. Many auto parts stores offer this service for free. The codes will point you to the specific system having trouble.

- Inspect for Visible Issues:

- Air Filter: A completely clogged air filter can restrict airflow. Check if it’s extremely dirty and consider replacing it.

- Vacuum Hoses: As mentioned earlier, visually inspect all rubber hoses connected to the intake manifold for cracks or disconnections.

- Consider Common Culprits (DIY Friendly):

- Clean the MAF Sensor: This is often the simplest and most effective first step for this particular symptom. Use the correct MAF cleaner.

- Clean the IAC Valve: If your car has one, cleaning it can also resolve many idle-related issues.

- Listen and Observe:

- When you try to start it, do you hear any unusual noises? Hissing sounds (vacuum leak)? A weak whine from the fuel pump?

- Does it feel like it’s starving for fuel?

- When to Call a Professional:

- If you’ve cleaned parts and checked for obvious issues without success.

- If you don’t feel comfortable performing the repairs yourself.

- If you suspect a failing fuel pump or other internal engine components.

- If the “Check Engine” light is on and the codes are complex or point to less accessible components.

Remember to always disconnect the battery before working on electrical components and allow the engine to cool completely before touching any parts.

Tools You Might Need

For some of these fixes, you might only need a few basic tools found in most home garages. For others, specialized equipment might be necessary.

| Tool | Purpose | Beginner Friendliness |

|---|---|---|

| Screwdrivers (Phillips and Flathead) | Disconnecting air intake hoses, removing sensor housing. | Very High |

| Socket Set/Wrenches | Removing components secured by bolts (e.g., IAC valve housing). | High |

| MAF Sensor Cleaner Spray | Specifically for cleaning MAF sensor elements. | Very High |

| Throttle Body Cleaner Spray | For cleaning IAC valves and throttle plates. | High |

| Multimeter | Testing electrical components like the ECT sensor (advanced DIY). | Medium |

| OBD-II Code Reader | Retrieving diagnostic trouble codes (essential if check engine light is on). | High |

| Pliers (various types) | Gripping hoses, removing clamps. | High |

| Safety Glasses & Gloves | Personal protection. | Very High |

For more complex diagnostics like fuel pressure testing or smoke tests, it’s best to entrust these tasks to a qualified mechanic with the proper equipment. But for cleaning sensors and hoses, a basic toolkit is often all you need.

Understanding Diagnostic Trouble Codes (DTCs)

If your “Check Engine” light is illuminated, reading the Diagnostic Trouble Codes (DTCs) is your first and most important step. An OBD-II scanner (On-Board Diagnostics version 2) plugs into a port typically found under the dashboard on the driver’s side.

These codes are like error messages from your car’s computer. For example:

- P0171: System Too Lean (Bank 1) – This often points to a vacuum leak or a MAF sensor issue.

- P0507: Idle Control System RPM Higher Than Expected – This strongly suggests a problem with the IAC valve or a significant vacuum leak.

- P0110-P0119: Intake Air Temperature (IAT) or Engine Coolant Temperature (ECT) Circuit Range/Performance – Indicates issues with sensors related to air or engine temperature.

Numerous online resources and automotive forums can help you decipher what these codes mean and suggest specific troubleshooting steps for your vehicle make and model. For instance, sites like CarCareKOREA’s OBD-II Code Library offer explanations for various codes.

When to Seek Professional Help

While many common car issues are DIY-friendly, some tasks are best left to seasoned professionals. If you encounter any of the following, don’t hesitate to visit a trusted mechanic:

- Lack of Confidence: If you’re unsure about any step or feel overwhelmed, it’s safer and often more cost-effective in the long run to let an expert handle it.

- Specialized Tools Required: Tasks like fuel pressure testing, internal engine diagnostics, or complex electrical troubleshooting often need specialized equipment that most DIYers don’t own.

- Persistent Issues: If you’ve tried basic fixes like cleaning sensors and checking for vacuum leaks, but the problem persists, a professional can perform more in-depth diagnostics.

- Safety Concerns: Working with fuel systems or complex engine components carries risks. If you’re not comfortable with the safety procedures, avoid the task.

- Major Component Replacement: Replacing a fuel pump, engine sensors deep within the engine bay, or other major parts can be time-consuming and technically demanding.

Frequently Asked Questions (FAQ)

Q1: My car starts fine in warm weather but dies when cold. What’s the cause?

A1: Cold stalling usually means the engine isn’t getting the right air-fuel mixture. Common causes are a dirty MAF sensor, a faulty idle air control valve, or vacuum leaks.

Q2: Can I clean the MAF sensor myself?

A2: Yes. Use only MAF sensor cleaner spray, never carb or brake cleaner. Remove the sensor, spray it, let it dry, and reinstall. If cleaning doesn’t help, replacement may be needed.

Q3: How do I know if my idle air control (IAC) valve is bad?

A3: Symptoms include rough idle, stalling at stops, or the engine dying when cold. Cleaning the IAC valve often helps, but replacement may be required if it fails.

Q4: Can a vacuum leak cause my car to stall after starting?

A4: Yes. Vacuum leaks let in unmetered air, creating a lean mixture. This is worse during cold starts and often causes stalling until the engine warms up.

Recent Posts

Tired of wrestling with your chains in the freezing cold? Discover how auto-fixing snow chains tighten themselves, giving you the ultimate effortless grip for a safer winter drive.

Struggling with that stubborn, hazy film on your car's glass? Discover the best oil film removers that will give you flawless, crystal-clear vision for a safer drive.