Can you make a front-wheel drive car rear-wheel drive? Yes, it’s technically possible, but it’s an extremely complex, expensive, and impractical modification for most. It involves significant mechanical changes, often rebuilding much of the car’s drivetrain and chassis. For most drivers, it’s not a feasible or cost-effective conversion.

Ever wondered if you could give your everyday front-wheel drive (FWD) car the sporty feel of rear-wheel drive (RWD)? Many car enthusiasts dream of this transformation, envisioning better handling and that classic RWD driving experience. It’s a common topic of discussion at car meets and online forums, often sparked by the desire for more performance or a unique build. While the thought is exciting, the reality of converting a FWD car to RWD is far more complicated than it might seem.

This guide will break down what’s involved, why it’s such a big undertaking, and what you might consider instead. We’ll look at the technical hurdles, the costs, and whether it’s a project truly worth pursuing for the average car owner. Let’s dive into the nitty-gritty of this intriguing automotive question.

Understanding Front-Wheel Drive (FWD) vs. Rear-Wheel Drive (RWD)

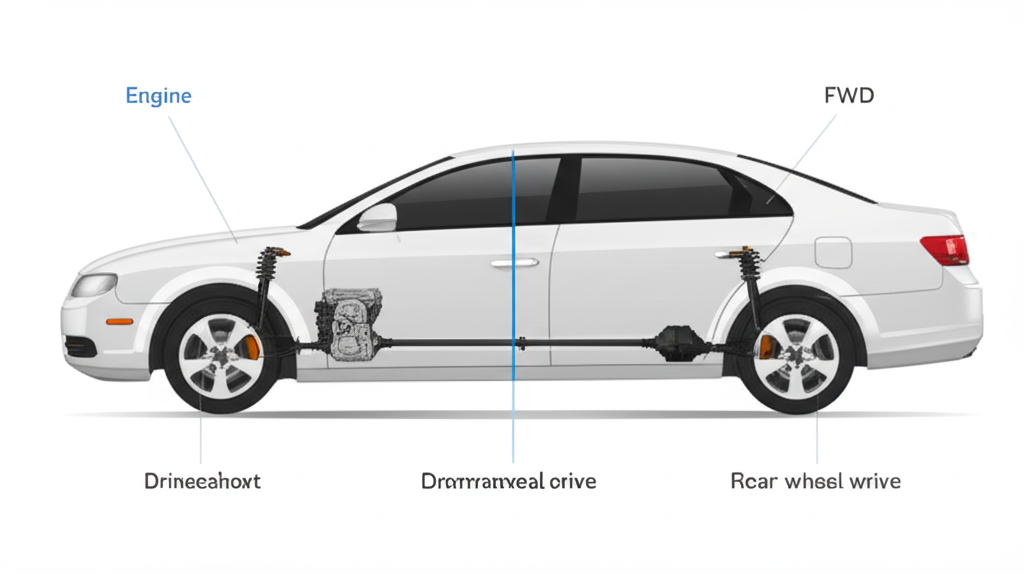

Before we talk about changing things, it’s crucial to grasp how FWD and RWD systems work. This will help you understand why converting one to the other is such a massive job.

How Front-Wheel Drive (FWD) Works

In a FWD car, the engine’s power is sent to the front wheels. These wheels not only propel the car forward but also steer it. This setup is common in most sedans and compact cars for several good reasons:

- Simplicity: The engine, transmission, and drive wheels are all in the front, reducing the need for a long driveshaft running to the back. This often means fewer parts and a lighter vehicle.

- Space Efficiency: With the drivetrain consolidated at the front, there’s more interior space for passengers and cargo. This is a big win for family cars and everyday commuters.

- Cost-Effectiveness: Manufacturing FWD vehicles is generally less expensive, which translates to lower purchase prices for consumers.

- Good Traction in Many Conditions: The weight of the engine is over the drive wheels, which can provide good traction, especially in slippery conditions like rain or light snow.

However, FWD cars can sometimes experience “torque steer” – a pulling sensation in the steering wheel under hard acceleration – and they might not offer the same dynamic handling characteristics that some enthusiasts crave, particularly during spirited driving.

How Rear-Wheel Drive (RWD) Works

In a RWD car, the engine’s power is sent to the rear wheels. The front wheels are solely responsible for steering. This is the traditional setup for many performance cars and trucks:

- Balanced Weight Distribution: Power going to the rear and steering at the front can lead to a more balanced feel, which is often preferred for sporty driving.

- Better Acceleration Performance: When accelerating hard, the weight of the car shifts towards the rear, pushing the drive wheels down and improving grip. This is why many race cars and high-performance vehicles are RWD.

- More Predictable Handling During Fun Driving: RWD cars can be easier to control when power sliding or drifting, as the rear wheels can be persuaded to lose traction in a more controlled manner.

The trade-offs for RWD often include less efficient interior space due to the driveshaft tunnel, potentially reduced traction in slippery conditions unless equipped with advanced traction control or winter tires, and a more complex drivetrain layout.

Can You Actually Make a FWD Car RWD?

The short answer is: yes, you can, but it’s an extraordinarily difficult and expensive project that’s rarely practical for most people. It’s not as simple as flipping a switch or adding a few parts. It requires a fundamental re-engineering of the car’s drivetrain and chassis.

Let’s break down why it’s so challenging. A FWD car is designed from the ground up with its drivetrain components – engine, transmission, differential, and axles – all integrated at the front. To convert it to RWD, you’re essentially trying to fit a completely different puzzle piece into a system that wasn’t built for it.

The Extensive Modifications Required for FWD to RWD Conversion

If you were to attempt such a conversion, you’d be looking at a massive undertaking. Here’s a glimpse into the major areas of modification:

1. Drivetrain Swaps and Integration

This is the heart of the conversion. You’d need to:

- Install a RWD Transmission: The FWD transmission isn’t designed to send power to the rear. You’d need to find a suitable RWD transmission that could be adapted to your engine. This often means fabricating custom mounts and driveshaft connections.

- Add a Rear Differential and Axles: FWD cars don’t have a rear differential. You’d need to source and install one, along with the necessary axles to connect to the rear wheels. This often involves cutting into the car’s chassis to mount the differential and run cooling lines.

- Fabricate a Driveshaft: A driveshaft is required to transmit power from the transmission to the rear differential. Custom fabrication would be essential to ensure it’s the correct length, diameter, and has the right U-joints for your specific setup.

- Engine and Transmission Mounting: Depending on the donor RWD components you use, the engine and transmission might need significant modification or even replacement to align properly with the new RWD drivetrain.

2. Chassis and Suspension Modifications

Mounting new RWD components isn’t easy. The car’s structure needs to accommodate them:

- Reinforcing the Chassis: The chassis of most FWD cars isn’t designed to handle the stresses of RWD components like a rear differential or the torque from a more powerful RWD-oriented engine. You’d likely need to reinforce the frame or body shell.

- Custom Suspension Setup: The rear suspension would need to be completely redesigned or replaced to incorporate the new differential and axles. This involves fabricating control arms, mounting points, and possibly altering the car’s ride height and geometry.

- Fuel Tank Relocation: In many FWD cars, the fuel tank is located in a place that obstructs the path of a RWD driveshaft. It might need to be relocated, which is a complex and potentially dangerous task.

3. Steering and Braking Systems

Even the systems that control the car’s motion need attention:

- Brake System Upgrade: If you plan to use a more powerful engine or achieve higher performance, the braking system will likely need an upgrade to handle the increased speeds. Sourcing and fitting larger rotors, calipers, and ensuring proper brake bias is critical.

- Steering Column and Linkage: While the front wheels still steer, integrating a new steering column or making adjustments for engine and transmission clearance might be necessary.

4. Electrical and Computer Systems

Modern cars are heavily reliant on electronics:

- ECU (Engine Control Unit) and Wiring: The car’s computer needs to communicate with the new transmission and potentially other engine management systems. Adapting or replacing the ECU and integrating its wiring harness can be incredibly complex.

- ABS and Traction Control: If your FWD car has ABS (Anti-lock Braking System) or traction control, these systems will need to be reconfigured or replaced to work with the new RWD setup. Faulty electronic systems can be dangerous.

Pros and Cons of Converting a FWD to RWD

Even though it’s difficult, let’s look at the potential upsides and definite downsides:

Potential Pros:

- Unique Driving Experience: The primary appeal is achieving the handling characteristics and feel of a RWD vehicle.

- Customization Project: For dedicated enthusiasts, it’s a chance to build a truly one-of-a-kind car.

- Potentially Better Performance: If done correctly with appropriate components, it could lead to improved acceleration and handling.

Significant Cons:

- Extreme Cost: This is by far the biggest drawback. Parts, specialized labor, and sheer time can easily run into tens of thousands of dollars, often exceeding the value of the original car.

- Complexity and Difficulty: This is not a beginner DIY project. It requires advanced fabrication skills, deep mechanical knowledge, and significant problem-solving abilities.

- Time Consuming: Expect this project to take hundreds, if not thousands, of hours.

- Reliability Issues: Unless built by absolute experts using well-matched components, the resulting car can be prone to numerous mechanical failures.

- Reduced Resale Value: While unique, custom conversions are often hard to sell, and many buyers will shy away from the risks and complexity.

- Legality and Insurance: Significant modifications can make a car illegal to drive on public roads without proper inspection and certification. Insuring a heavily modified vehicle can also be difficult and expensive.

What Are Your Options Instead?

Given the immense challenges of converting a FWD car to RWD, most people find it much more practical to explore other avenues that achieve similar goals:

1. Buy a RWD Car

This is the most sensible and cost-effective solution. There are many excellent RWD cars available on the used market that offer sporty handling and performance without the headaches of a conversion. Consider models like:

- Toyota 86 / Subaru BRZ (Affordable, nimble sports cars)

- BMW 2 Series (Great balance of luxury and RWD performance)

- Ford Mustang (Classic American muscle with RWD)

- Chevrolet Camaro (Another excellent muscle car option)

- Lexus RC (Stylish and comfortable RWD coupe)

Even some trucks and older RWD sedans can offer the desired driving feel.

2. Improve Your FWD Car’s Handling

While you can’t change the driven wheels, you can dramatically improve how your FWD car handles and feels through various upgrades:

- High-Performance Tires: This is the single most impactful upgrade for any car’s handling. Good tires provide better grip, stopping power, and steering response. Check out reputable tire guides from sources like Tire Rack for recommendations.

- Upgraded Suspension Components:

- Performance Shocks and Struts: These can reduce body roll and improve ride quality.

- Lowering Springs: A lower center of gravity improves stability.

- Sway Bars (Anti-Roll Bars): Thicker sway bars significantly reduce body roll during cornering.

- Strut Tower Braces: These reinforce the chassis and improve steering feel.

- Brake Upgrades: Better brake pads, rotors, and fluid can improve stopping performance and feel, giving you more confidence.

- Weight Reduction: Removing unnecessary weight (e.g., spare tire for track days, lighter interior components) can make any car feel more nimble.

- Alignment Adjustments: A performance-oriented alignment can optimize tire contact and steering response.

3. Consider a “Ring-Dinger” Conversion Kit (Rare and Specific)

In very rare cases, for specific car models, aftermarket companies might offer conversion kits. These are typically for older, classic cars where there’s a strong enthusiast community and demand. These kits still involve significant work but are more curated than a complete custom build. Search for specific model communities or performance shops that specialize in such niche conversions, but be prepared for limited options and high costs.

Tools and Skills Needed for Advanced Work

If you were to even contemplate a project like this, you would need a comprehensive toolkit and advanced skills:

Essential Tools:

- Full metric and imperial socket sets

- Wrench sets

- Torque wrenches

- Jack and jack stands (heavy-duty)

- Engine hoist and stands

- Transmission jack

- Welding equipment (MIG or TIG)

- Cutting tools (angle grinder, plasma cutter, reciprocating saw)

- Metal fabrication tools (metal brake, tubing bender)

- Diagnostic scan tools

- Multimeter for electrical troubleshooting

- Specialized transmission and differential tools

Required Skills:

- Advanced mechanical knowledge

- Welding and fabrication expertise

- Drivetrain component installation and alignment

- Suspension geometry understanding

- Electrical system diagnosis and modification

- Problem-solving and troubleshooting creativity

For reference on fabrication techniques, resources like The American Welding Society (AWS) offer valuable information on welding safety and best practices.

FAQ: Your Questions About FWD to RWD Conversions Answered

Here are some common questions car owners have about this topic:

Q1: Is it ever cost-effective to convert a FWD car to RWD?

A: Almost never. The labor, specialized parts, and potential for costly mistakes make it far more expensive than selling your FWD car and buying a RWD vehicle that was engineered from the factory for that setup.

Q2: What’s the easiest way to make a FWD car feel sportier?

A: The most impactful and cost-effective ways are upgrading to high-performance tires, improving the suspension with quality shocks, struts, and sway bars, and ensuring your brakes are in top condition. A performance alignment can also make a noticeable difference.

Q3: Can I just swap the engine and transmission from a RWD car into my FWD car?

A: It’s still incredibly complex. Even if the engine bolts up somewhat, you’ll still need to figure out how to connect it to a RWD transmission, run a driveshaft, install a rear differential, and modify the chassis and suspension to all work together. The FWD chassis just isn’t designed for these RWD components.

Q4: Will converting a FWD to RWD affect my car’s weight distribution?

A: Yes, significantly. FWD cars typically have more weight over the front wheels. A RWD conversion could potentially shift weight balance, but achieving ideal RWD balance (often 50/50) is very difficult and depends heavily on the specific parts and their placement during the conversion.

Q5: What are the main reasons cars are designed as FWD vs. RWD?

A: FWD is often chosen for packaging efficiency, lower cost, and good traction in everyday conditions. RWD is preferred for performance driving, better handling balance, and load-carrying capacity (in trucks), offering a more engaging driving experience for enthusiasts.

Q6: Can I legally drive a converted FWD to RWD car on the street?

A: It can be very difficult. Most jurisdictions have strict vehicle modification laws and require extensive inspections and certifications for safety and emissions. You would need to research your local laws thoroughly, consult with your DMV or equivalent, and potentially undergo rigorous safety testing.

Q7: Are there any popular car models that are commonly converted from FWD to RWD?

A: Conversions are extremely rare for modern FWD cars. They are more likely to be attempted on older, classic vehicles where there’s a strong enthusiast following and potentially a simpler chassis design. Even then, it remains a monumental undertaking.

Conclusion

So, can you make a front-wheel drive car rear-wheel drive? Technically speaking, with enough money, time, and expertise, virtually anything is achievable in the automotive world. However, for the vast majority of car owners, the answer boils down to practicality. The conversion process is so

Recent Posts

Looking for a quick, affordable way to customize your bike? Discover why this simple oil filler cap is the must-have mod for your CBR 650 R.

Keep your Perkins engine protected with our ultimate quality replacement oil filler cap. It's designed to deliver a perfect, leak-proof seal for lasting performance and peace of mind.