Yes, you can often add power steering to a car that didn’t originally have it, but it’s a complex and potentially expensive modification. It typically involves installing a power steering pump, reservoir, steering gearbox or rack, hoses, and sometimes a new steering column. While possible, it requires significant mechanical skill, specialized parts, and careful consideration of safety and legality.

Does turning your steering wheel feel like a workout? You’re not alone! Many older cars, and some simpler modern designs, don’t come with power steering. This can make parking and low-speed maneuvering a real challenge, especially for those with less upper body strength. The good news is, you might be wondering, “Can you add power steering to a car?” The answer is often yes, but it’s not as simple as changing a tire. Think of it as a significant upgrade, like giving your car a special feature it never had. In this guide, I’ll break down what’s involved, why it’s a big project, and what you need to consider before diving in. We’ll cover the parts, the challenges, and whether it’s the right move for your ride.

Understanding Power Steering: How It Works

Before we talk about adding it, let’s quickly understand what power steering does. In simple terms, power steering is a system that helps you turn the wheels of your car with less effort. Instead of you doing all the muscle work, it uses hydraulic fluid (or electric assistance) to multiply the force you apply to the steering wheel. This makes steering feel lighter and much easier, especially when you’re stopped or moving slowly.

The Two Main Types of Power Steering

Most cars today use one of two main types of power steering systems:

- Hydraulic Power Steering: This is the most common type for many years. A pump driven by the engine circulates hydraulic fluid. When you turn the steering wheel, a control valve directs this fluid to assist the movement of a piston, which in turn helps turn the wheels.

- Electric Power Steering (EPS): Newer cars are increasingly using EPS. Instead of a hydraulic pump, an electric motor directly assists the steering. This system is generally more fuel-efficient and can offer variable assistance levels depending on speed.

For retrofitting an older car, hydraulic power steering is usually the more common and practical choice, though electric conversions are becoming more feasible with advanced aftermarket kits.

Can You Add Power Steering to a Car? The Short Answer

Technically, yes, it is often possible to add power steering to a car that was not originally manufactured with it. However, this is not a simple bolt-on modification. It’s a significant undertaking that requires a deep understanding of automotive mechanics, access to specialized parts, and considerable labor. It’s often a project best left to experienced mechanics or dedicated DIY enthusiasts with a well-equipped workshop.

Why Add Power Steering? The Benefits

If your car lacks power steering, you’ve likely experienced its downsides. Adding it can bring several advantages:

- Easier Steering: The most obvious benefit. Parking, U-turns, and navigating tight spaces become effortless.

- Reduced Driver Fatigue: Long drives or city driving can be tiring when you have to constantly fight the steering wheel. Power steering significantly reduces this strain.

- Improved Maneuverability: Especially for drivers with physical limitations, power steering can make a car much more accessible and easier to control.

- Increased Vehicle Value (Potentially): While the cost of adding power steering might not always be recouped, a car that handles more easily could be more appealing to a wider range of buyers.

The Challenges of Adding Power Steering

Now, let’s get to the heart of it: why is this a big project? Adding power steering involves integrating several components that your car likely doesn’t have. This isn’t like changing the oil; it’s fundamentally altering the car’s steering system.

Here are the major hurdles:

- Component Compatibility: Finding compatible parts is crucial. You need a power steering gearbox or rack that physically fits your car’s chassis and steering linkage.

- Space Constraints: Engine bays can be cramped. You need to find space for the power steering pump, reservoir, and hoses without interfering with other components.

- Engine Drive Requirements: Hydraulic power steering pumps are typically driven by a belt connected to the engine’s crankshaft. Your engine might not have the necessary mounting points or pulley systems for this.

- Plumbing and Fluid Leaks: Running high-pressure hydraulic lines requires careful routing and secure fittings to prevent leaks, which can be very dangerous.

- Structural Modifications: In some cases, you might need to modify the car’s frame or firewall to accommodate new steering components.

- Cost: Parts and labor for such a custom job can add up quickly, often making it more economical to trade in for a car that already has power steering.

- Safety and Reliability: An improperly installed system can be a major safety hazard, leading to loss of steering control. It’s vital the work is done correctly by someone qualified.

- Legality and Inspections: Depending on your location, significant modifications like this may need to pass specific inspections to ensure they meet safety standards.

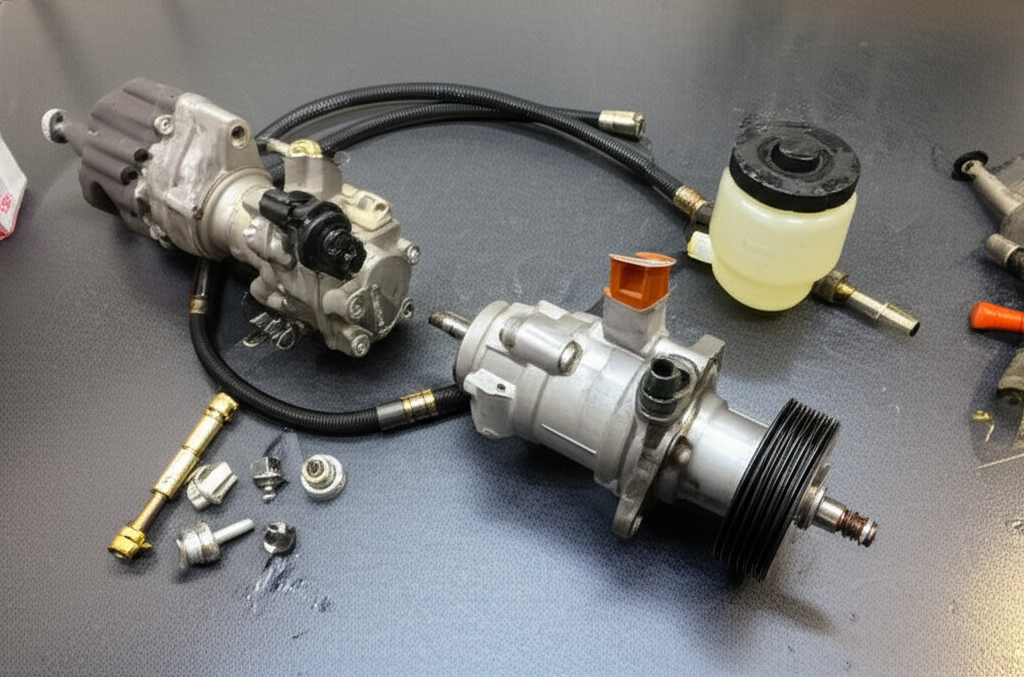

Essential Components for a Power Steering Conversion

If you’re considering this conversion, here’s a breakdown of the parts you’ll typically need:

1. Power Steering Gearbox or Rack and Pinion

This is the heart of the system that replaces your manual steering gear. You’ll need one that’s designed to integrate with your car’s steering column and front suspension.

- Gearbox: Found in many older cars, it’s a more robust unit that translates steering wheel movement into lateral movement of the steering linkage.

- Rack and Pinion: Common in front-wheel-drive cars and many modern rear-wheel-drive vehicles. It uses a rack with teeth that meshes with a pinion gear attached to the steering column.

2. Power Steering Pump

This pump is driven by the engine to provide the hydraulic pressure needed to assist steering. It needs to be mounted securely to the engine and connected via belt to the crankshaft pulley.

3. Power Steering Reservoir

This holds the hydraulic fluid. It’s usually mounted near the pump and is connected to it with a hose.

4. Drive Belt and Pulleys

You’ll need a belt specifically sized to drive the pump, and your engine must have the correct pulleys. This often means adding an extra pulley or using a different belt configuration.

5. Hoses and Fittings

High-pressure and low-pressure hoses are needed to connect the pump, reservoir, and steering gear. These must be rated for automotive power steering systems and installed with leak-proof fittings.

6. Power Steering Fluid

A specific type of hydraulic fluid is required to operate the system. Always use the fluid recommended by the manufacturer of your power steering components.

7. Mounting Brackets

Custom brackets might be required to mount the power steering pump and reservoir to your engine and chassis.

8. Steering Column Modifications (Sometimes)

Depending on the gearbox or rack you use, minor modifications to the steering column or intermediate shaft might be necessary to connect it properly.

Step-by-Step: The General Process (For Informational Purposes)

It’s important to stress that this is a highly complex job. The exact steps will vary significantly depending on the car model and the chosen power steering system. This is a simplified overview to illustrate the complexity.

Phase 1: Planning and Parts Acquisition

This is the most critical phase. Rushing here leads to problems later.

- Vehicle Assessment: Determine if your car’s chassis can accept a different steering system. Research common or compatible upgrades for your specific model. Forums and owner clubs can be invaluable resources.

- Parts Sourcing: Identify a suitable power steering gearbox or rack. This might be from a similar model car factory-equipped with power steering, or an aftermarket conversion kit. Source the pump, reservoir, hoses, belts, and mounting hardware. New, remanufactured, or used parts can be options, but quality is paramount. Original equipment manufacturer (OEM) parts are generally preferred for reliability.

- Manual Study: Obtain a factory service manual for your car and for the car the donor power steering components came from. Even if a direct conversion isn’t documented, these manuals provide critical information on steering geometries, mounting procedures, and fluid requirements. For alternative steering systems, check guides like those from Stewart Warner, which often detail installation considerations for various gauge and system integrations.

Phase 2: Installation

This phase requires significant mechanical skill and potentially specialized tools.

- Remove Old Steering Components: Safely lift and support the vehicle. Disconnect the manual steering linkage, remove the manual steering box or rack, and any associated components.

- Install New Steering Gear: Mount the new power steering gearbox or rack and pinion. This often involves aligning mounting holes and potentially fabricating or modifying brackets. Connect it to the steering shaft.

- Mount Power Steering Pump and Reservoir: Find a suitable location on the engine for the pump. Install mounting brackets and secure the pump. Mount the reservoir.

- Connect Drive System: Install the correct belt and pulleys to drive the power steering pump from the engine’s crankshaft. Ensure proper belt tension.

- Run Hydraulic Lines: Carefully route the high-pressure and return hoses from the pump to the steering gear and back to the reservoir. Ensure they are not rubbing against hot engine parts or sharp edges. Use appropriate fittings and secure them tightly.

- Fill and Bleed the System: Fill the reservoir with the correct type of power steering fluid. With the engine off, turn the steering wheel lock-to-lock several times to help draw fluid through the system. Then, start the engine and slowly turn the wheel lock-to-lock again, topping up the fluid as needed. Bleeding removes air bubbles, which are crucial for proper operation and can damage the pump if ignored.

Phase 3: Testing and Adjustments

- Check for Leaks: After running the engine and cycling the steering, thoroughly inspect all hose connections and components for any signs of fluid leakage.

- Test Drive: On a lifted vehicle, check steering operation. Once satisfied, perform a slow, careful test drive in a safe area. Test steering at various speeds, paying close attention to ease of turning, responsiveness, and any unusual noises.

- Final Adjustments: Make any necessary adjustments to belt tension, hose routing, or fluid levels.

DIY vs. Professional Installation

Deciding whether to tackle this yourself or hire a professional is a major consideration.

DIY Installation:

- Pros: Significant cost savings on labor, deep satisfaction from a complex project completed, and a thorough understanding of your car’s new system.

- Cons: Requires extensive mechanical knowledge, specialized tools, a dedicated workspace, and a high risk of errors that can be dangerous and costly to fix. Finding compatible parts can be extremely challenging.

Professional Installation:

- Pros: Expertise ensures the system is installed correctly and safely, often comes with a warranty on labor and parts, and saves you the time and frustration of a complex job.

- Cons: Significantly more expensive due to labor costs. You’ll need to find a shop experienced with custom retrofits, which can be difficult.

For most beginners, professional installation is highly recommended. The complexity and safety implications of power steering systems mean that even minor errors can have severe consequences on the road.

Cost Considerations for Adding Power Steering

The cost can vary wildly. You might spend anywhere from $500 for a basic, used parts conversion (done yourself) to well over $3,000-$5,000+ for a professionally installed kit using new, high-quality components.

| Component Type | Estimated Cost Range (USD) | Notes |

|---|---|---|

| Used Power Steering Gearbox/Rack | $100 – $400 | Requires thorough inspection; compatibility is key. |

| New/Remanufactured Gearbox/Rack | $300 – $800 | More reliable than used. |

| Power Steering Pump & Reservoir Kit | $100 – $300 | Can be engine-specific. |

| Hoses, Fittings & Fluid | $50 – $200 | Essential for a leak-free system. |

| Mounting Brackets & Hardware | $50 – $200 | May require custom fabrication. |

| Labor (Professional Installation) | $800 – $3,000+ | Highly dependent on shop rates and complexity. |

| Total Estimated Cost (DIY) | $450 – $2,000+ | Excludes tools and potential mistakes. |

| Total Estimated Cost (Professional) | $1,500 – $5,000+ | Varies greatly by vehicle and parts chosen. |

When budgeting, always factor in unexpected costs. If you’re not a seasoned mechanic, research the average labor rates in your area for this type of custom work. You can also explore forums dedicated to your car model to see what others have paid for similar conversions.

Alternatives to a Full Power Steering Conversion

If a full conversion seems too daunting or expensive, are there other options?

- Manually Lowering Steering Effort: Sometimes, simply ensuring your existing manual steering system is in top condition can help. Fresh grease in the steering column or universal joints, and ensuring wheel alignment is perfect, can reduce friction.

- Electric Power Steering (EPS) Conversion Kits: For some popular classic cars, aftermarket companies offer EPS kits. These typically use an electric motor to assist the steering rack, eliminating the need for a hydraulic pump, reservoir, and belts. They can be easier to install as they don’t rely on the engine for power, but they are often expensive and may still require significant modification to fit. Sites like Flaming River offer specialized kits for certain vehicles, showcasing the evolving market for these systems.

- Aftermarket Steering Wheels: While they don’t add power assistance, some steering wheels have a larger diameter or slightly different grip, which can feel like they offer more leverage. This is a very minor perceptual change, not a functional one.

Is It Worth It? Making the Decision

Adding power steering to a car that never had it is a project driven by necessity or a desire for a significantly improved driving experience. It’s a substantial modification that impacts a critical safety system.

Consider these points:

- Your Car’s Value: Is the cost of the conversion justified by the car’s overall value or your emotional attachment to it?

- Your Mechanical Skills: Be honest about your abilities. If welding, custom fabrication, and hydraulic systems are new to you, it’s probably not a DIY project.

- Intended Use: If the car is a daily driver that sees a lot of city traffic, the benefits of power steering are immense. If it’s a weekend cruiser or track car where steering feel is paramount, you might reconsider.

- Availability of Parts: Can you find compatible parts readily, or will you be hunting for rare, expensive components?

For many, the most practical solution if manual steering is a struggle is to sell the current vehicle and purchase one that came with power steering from the factory. However, for enthusiasts who love their specific car and are committed to improving it, the reward of a successful power steering conversion can be very satisfying.

Frequently Asked Questions (FAQ)

Q1: How difficult is it to add power steering to a car?

It is generally a very difficult and complex modification. It requires significant mechanical knowledge, specialized tools, and often custom fabrication. It’s not a typical DIY task for beginners.

Q2: Can I add power steering to my classic car?

Yes, it’s often possible, especially for classic cars with simpler mechanical systems. However, parts compatibility and finding space for the components can be major challenges. Dedicated kits are sometimes available for popular classic models.

Q3: What’s the difference between hydraulic and electric power steering? Which is better for a conversion?

Hydraulic uses a pump driven by the engine and fluid

Recent Posts

Looking for a quick, affordable way to customize your bike? Discover why this simple oil filler cap is the must-have mod for your CBR 650 R.

Keep your Perkins engine protected with our ultimate quality replacement oil filler cap. It's designed to deliver a perfect, leak-proof seal for lasting performance and peace of mind.